Two more | Inner Mongolia Huineng Coal Power PIDS Belt Intelligent Dry Sorting Machine Successfully Delivered

Release Date:2023-05-26 Source: Number of views:98

Two sets of PIDS Belt Intelligent Dry Sorting Machine were successfully shipped.

On May 24th, two sets of PIDS Belt Intelligent Dry Sorting Machine were sent to the site of Huineng Coal & Electricity Changtan Open Pit Coal Mine Project. Taiho Zhuo Hai strictly followed the standard process of warehousing and loading to ensure that the equipment was delivered to the customer as scheduled.

The trucks drive out of Taiho Zhuohai plant, PIDS will take its own mission to the next destination, to open up a more environmentally friendly, energy-saving and efficient coal selection road for the enterprise.

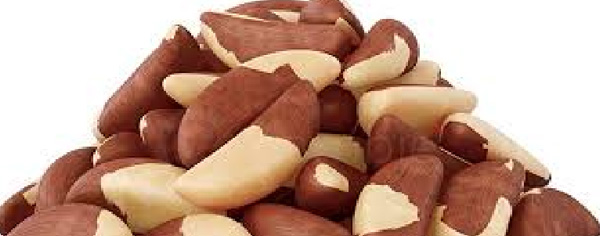

PIDS Belt Intelligent Dry Separator

Using dual-energy X-ray/visible full-spectrum multispectral scanning imaging system to collect images of materials on the conveyor belt, analyzing the images and judging the material types through deep learning image recognition technology, accurately controlling high-pressure wind blowing gangue and impurities, and realizing precise, efficient and energy-saving fully automatic coal sorting.

PIDS Belt Intelligent Dry Sorting Machine not only realizes fully automatic raw coal sorting with more than 95% recognition accuracy, but also is able to overcome environments unsuitable for traditional wet beneficiation, such as lack of water, severe cold, and easy sludging of ores, etc., and improves the lifespan and value of the mines with a greener and more environmentally friendly sorting process.

Taiho Zhuo Hai VCS/VDS Vertical Intelligent Dry Sorting Machine utilizes dual-energy X-ray scanning imaging system to collect the image of free-falling/chute-falling materials, with higher signal-to-noise ratio, wider adaptability to the particle size, and the lower limit of the sorting particle size is as low as 6mm. the materials are free-falling to the chute after discharging from the vibrating screen, with no physical contact throughout the whole process, so there is no risk of mechanical failure; the spraying system is arranged horizontally, so it is not easy to be blocked. The material can be accelerated to 3m/s when it falls to the lookout point, and the speed is about 5m/s when it falls to the execution point, which is 30% higher than the processing capacity of belt-type intelligent dry separator under the same conditions.

Two sets of PIDS Belt Intelligent Dry Sorting Machine were successfully shipped.

On May 24th, two sets of PIDS Belt Intelligent Dry Sorting Machine were sent to the site of Huineng Coal & Electricity Changtan Open Pit Coal Mine Project. Taiho Zhuo Hai strictly followed the standard process of warehousing and loading to ensure that the equipment was delivered to the customer as scheduled.

The trucks drive out of Taiho Zhuohai plant, PIDS will take its own mission to the next destination, to open up a more environmentally friendly, energy-saving and efficient coal selection road for the enterprise.

PIDS Belt Intelligent Dry Separator

Using dual-energy X-ray/visible full-spectrum multispectral scanning imaging system to collect images of materials on the conveyor belt, analyzing the images and judging the material types through deep learning image recognition technology, accurately controlling high-pressure wind blowing gangue and impurities, and realizing precise, efficient and energy-saving fully automatic coal sorting.

PIDS Belt Intelligent Dry Sorting Machine not only realizes fully automatic raw coal sorting with more than 95% recognition accuracy, but also is able to overcome environments unsuitable for traditional wet beneficiation, such as lack of water, severe cold, and easy sludging of ores, etc., and improves the lifespan and value of the mines with a greener and more environmentally friendly sorting process.

Taiho Zhuo Hai VCS/VDS Vertical Intelligent Dry Sorting Machine utilizes dual-energy X-ray scanning imaging system to collect the image of free-falling/chute-falling materials, with higher signal-to-noise ratio, wider adaptability to the particle size, and the lower limit of the sorting particle size is as low as 6mm. the materials are free-falling to the chute after discharging from the vibrating screen, with no physical contact throughout the whole process, so there is no risk of mechanical failure; the spraying system is arranged horizontally, so it is not easy to be blocked. The material can be accelerated to 3m/s when it falls to the lookout point, and the speed is about 5m/s when it falls to the execution point, which is 30% higher than the processing capacity of belt-type intelligent dry separator under the same conditions.