Industry News | Talk about those building materials industry

Release Date:2020-04-23 Source: Number of views:94

Do you know how to automatically quantitatively pack cement, putty powder, caulking, plugging king, gypsum powder; anticorrosive coatings, refractory materials, latex paints, dry mortar, waterproof emulsions; these special powders and liquids?

Building materials products are usually processed in large sizes in tons of batches before they are divided and put into the market before they need to be quantitatively divided. But manual packaging, high labor costs, difficult to manage personnel, low efficiency, etc., are the enterprise's troubles, and automatic packaging machine can not only solve these problems, but also to protect the enterprise's environment clean, workers' health.

When it comes to automatic packaging machine in the building materials and waterproofing industry, we have to say that Zengran packaging powder and liquid packaging equipment, which is widely praised in the industry and trusted by well-known enterprises in the building materials and waterproofing industry.

(Some cooperative building materials customers)

Zengran's powder and liquid packaging equipment is highly trusted because of its high degree of automation, simple operation, stable equipment, improving the traditional production process, labor environment, saving labor (3-4 people), reducing the labor intensity of workers, lowering the production cost and improving the production efficiency.

A frontrunner in the packaging industry

As the front-runner in the packaging industry, Zengran Packaging has been committed to providing customers with high-level packaging machines. Today, I would like to share with you the powder and liquid packaging equipment provided by Zengran Packaging for building materials enterprises.

Zengran Liquid Packaging Machine

Zengran Packaging's liquid packaging machine adopts filling machine with high degree of intelligence; it is controlled by programmable controller (PLC), which can effectively control the rotor pump speed and time with very accurate calculation precision. Machine operation, output, etc. are shown on the touch screen, the human-machine interface is more friendly. Unique anti-drip filling valve can effectively prevent the bag mouth contamination caused by dripping during the sealing process of the filling machine. The filling machine is made of 304 stainless steel material, which is anti-corrosive.

Unique large teeth sealing, to ensure that the sealing is firm; anti-drip system, so that the material in the canning said precise start and stop, and set the suction back function, to avoid sealing the moment the material dripping contamination of the seal.

Zengran Powder Packaging Machine

Packaging of powder packaging machine body material with solid materials, accessories is the use of domestic and foreign well-known accessories, equipment durability, the current Zengran brand equipment for a long time up to 17 years; equipment adopts split silo, easy to clean up, can increase the weighing type measurement mechanism, flap type discharging; unique static electricity elimination technology to prevent dust inhalation, sealing is more solid, no worry about the broken bag; unique multi-layer dust removal system, so that the first time to absorb the dust recovery to avoid bag mouth pollution can not seal; servo motor-driven screw speed setting, performance, weighing accuracy; servo motor-driven screw, speed setting, performance, so that equipment service life growth; servo motor-driven screw, speed setting, performance, weighing accuracy. Unique multi-layer dust removal system, so that the dust is sucked away and recycled at the first time, avoiding the bag mouth contamination can not be sealed, but also make the site environment control better, so that the equipment service life grows; servo motor-driven helix, speed can be set, stable performance, weighing and weighing accurately.

Zengran Packaging Quality Service

A good product, not only need quality assurance, perfect after-sales service mechanism is also very important.

(Inside the workshop)

Zengran's service team has a perfect customer satisfaction system: professional pre-sales consulting and program design; technical training and program implementation during sales; timely door-to-door service after sales; personalized solutions to customer needs and precise programs.

(After-sales service personnel commissioning equipment for enterprises)

In 2020, when the whole country was attacking against the epidemic and urgently needed to resume work and production, Zengran Packaging's service team carried out an activity called "After-sales Service Visit Miles", which started from Zengran's headquarter in Hefei to all parts of the country, spanning many provinces and cities, such as Henan Province, Gansu Province and Anhui Province, etc., and warmed up the people by providing sincere service to assist partners in resumption of work and production.

(Miles of after-sales service visits)

Good quality, good service, Zengran packaging, worthy of your trust.

Do you know how to automatically quantitatively pack cement, putty powder, caulking, plugging king, gypsum powder; anticorrosive coatings, refractory materials, latex paints, dry mortar, waterproof emulsions; these special powders and liquids?

Building materials products are usually processed in large sizes in tons of batches before they are divided and put into the market before they need to be quantitatively divided. But manual packaging, high labor costs, difficult to manage personnel, low efficiency, etc., are the enterprise's troubles, and automatic packaging machine can not only solve these problems, but also to protect the enterprise's environment clean, workers' health.

When it comes to automatic packaging machine in the building materials and waterproofing industry, we have to say that Zengran packaging powder and liquid packaging equipment, which is widely praised in the industry and trusted by well-known enterprises in the building materials and waterproofing industry.

(Some cooperative building materials customers)

Zengran's powder and liquid packaging equipment is highly trusted because of its high degree of automation, simple operation, stable equipment, improving the traditional production process, labor environment, saving labor (3-4 people), reducing the labor intensity of workers, lowering the production cost and improving the production efficiency.

A frontrunner in the packaging industry

As the front-runner in the packaging industry, Zengran Packaging has been committed to providing customers with high-level packaging machines. Today, I would like to share with you the powder and liquid packaging equipment provided by Zengran Packaging for building materials enterprises.

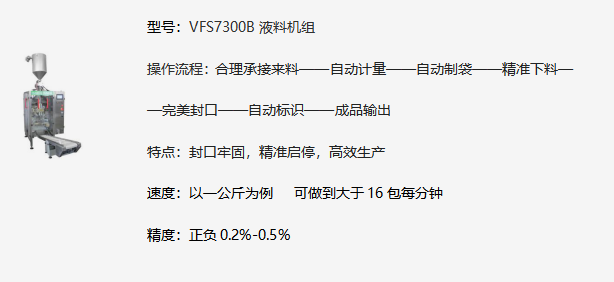

Zengran Liquid Packaging Machine

Zengran Packaging's liquid packaging machine adopts filling machine with high degree of intelligence; it is controlled by programmable controller (PLC), which can effectively control the rotor pump speed and time with very accurate calculation precision. Machine operation, output, etc. are shown on the touch screen, the human-machine interface is more friendly. Unique anti-drip filling valve can effectively prevent the bag mouth contamination caused by dripping during the sealing process of the filling machine. The filling machine is made of 304 stainless steel material, which is anti-corrosive.

Unique large teeth sealing, to ensure that the sealing is firm; anti-drip system, so that the material in the canning said precise start and stop, and set the suction back function, to avoid sealing the moment the material dripping contamination of the seal.

Zengran Powder Packaging Machine

Packaging of powder packaging machine body material with solid materials, accessories is the use of domestic and foreign well-known accessories, equipment durability, the current Zengran brand equipment for a long time up to 17 years; equipment adopts split silo, easy to clean up, can increase the weighing type measurement mechanism, flap type discharging; unique static electricity elimination technology to prevent dust inhalation, sealing is more solid, no worry about the broken bag; unique multi-layer dust removal system, so that the first time to absorb the dust recovery to avoid bag mouth pollution can not seal; servo motor-driven screw speed setting, performance, weighing accuracy; servo motor-driven screw, speed setting, performance, so that equipment service life growth; servo motor-driven screw, speed setting, performance, weighing accuracy. Unique multi-layer dust removal system, so that the dust is sucked away and recycled at the first time, avoiding the bag mouth contamination can not be sealed, but also make the site environment control better, so that the equipment service life grows; servo motor-driven helix, speed can be set, stable performance, weighing and weighing accurately.

Zengran Packaging Quality Service

A good product, not only need quality assurance, perfect after-sales service mechanism is also very important.

(Inside the workshop)

Zengran's service team has a perfect customer satisfaction system: professional pre-sales consulting and program design; technical training and program implementation during sales; timely door-to-door service after sales; personalized solutions to customer needs and precise programs.

(After-sales service personnel commissioning equipment for enterprises)

In 2020, when the whole country was attacking against the epidemic and urgently needed to resume work and production, Zengran Packaging's service team carried out an activity called "After-sales Service Visit Miles", which started from Zengran's headquarter in Hefei to all parts of the country, spanning many provinces and cities, such as Henan Province, Gansu Province and Anhui Province, etc., and warmed up the people by providing sincere service to assist partners in resumption of work and production.

(Miles of after-sales service visits)

Good quality, good service, Zengran packaging, worthy of your trust.