Taiho Case| Intelligent Sorting Helps Fortune Fruit Industry to Get Better Fruits at Better Prices

Release Date:2020-05-28 Source: Number of views:1073

"Since the selection of Taiho 4.0 Intelligent Fruit Sorting System, the accuracy of fruit sorting has been improved, the pass rate can reach more than 95%, the fruit loss rate reaches less than 5%, which reduces the cost and improves the quality of sorting for our company" The person in charge of the Fubai Fruit Industry said that although our country is a big country in the production of fruits, but it's not a strong country in the production of fruits. In order to improve the quality of fruit processing and product grade, the need for strict quality grading and size grading of fruit.

In 2007, rich hundred fruit industry limited company was identified as the country's only use of "China women's volleyball team special supply apple" logo of the enterprise. 2008, for the Beijing Olympic Games after the special supply of apples, general manager Li Jindou has been thinking about a problem: how to better play the brand effect, quality and quantity of supply, the company's industrial technological innovation, has been The company's industrial technology innovation has been imperative.

In order to better improve the quality of apples and maximize the brand effect, Fubai Fruit Industry introduced Taiho Photoelectric Intelligent Fruit Grading System in 2016.

6GF series intelligent fruit grading machine is independently developed and manufactured by Taiho Optoelectronics, which adopts for the first time the non-destructive air-drying and conveying technology of fruits, omni-directional multi-viewing angle vision technology, infrared identification dark injury technology, relying on Taiho Optoelectronics many years of accumulation of artificial intelligence sorting technology, cloud identification sorting technology and many other core technologies, omni-directional data collection and high-speed information processing, realizing the shape selection, color selection, quality selection (sugar, acidity Intelligent sorting (sugar, acidity). The results of grading and classification are clearly displayed, the product structure is reasonable, the system configuration meets the needs of the fruit industry, the degree of automation is high, and it is easy to learn and use.

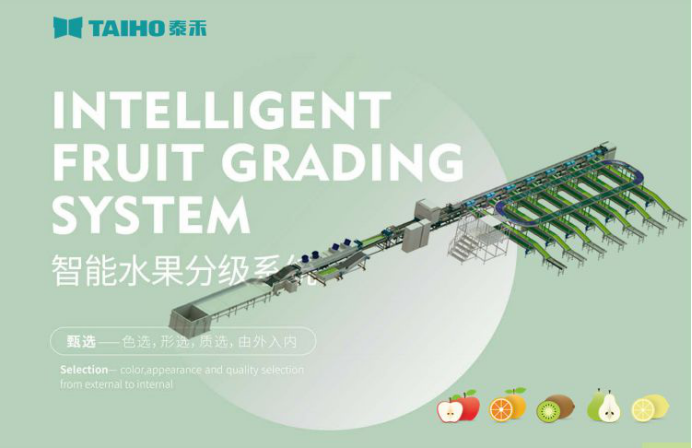

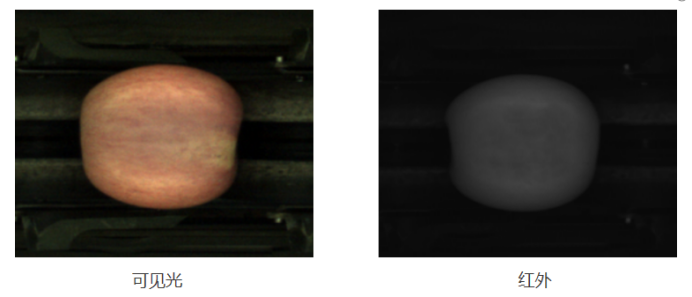

Internal Quality Inspection

Infrared identification of dark injury technology, detection of sugar content, mold heart disease and other internal physiological indicators.

The sample model established by adopting the fully transmissive detection technology and the new dynamic modeling method is more real and effective, and at the same time, it applies the multi-dimensional model coupling algorithm and the neural network algorithm, and is the first one to use the big data and the deep learning method to optimize the model continuously.

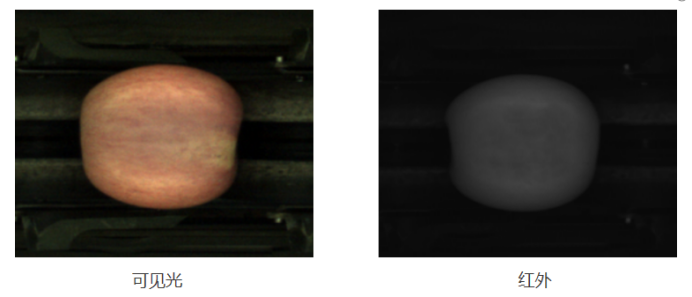

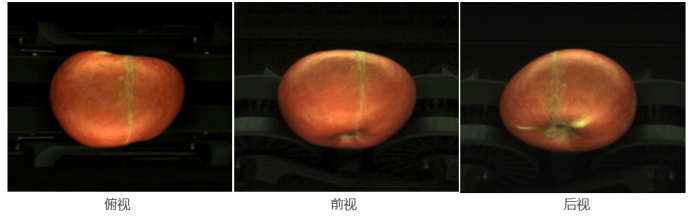

Appearance Quality Inspection

Omni-directional multi-view vision technology to detect fruit shape, color, defects and other external quality indicators.

Multiple high-resolution industrial camera lenses, with special LED light source system for all-round data acquisition, Gauss-Laplace hybrid model algorithm to solve the high-speed dynamic background target detection.

Weight Detection

Unique dynamic calibration as well as temperature compensation function to avoid measurement errors caused by environmental differences.

Single sensor and special fruit cup with four points of contact to avoid measurement errors caused by mechanical vibration problems, high-speed dynamic measurement of up to 1600 times/second, four levels of effective filtering to ensure fast detection and high accuracy of weight.

Density testing

Screens out fruits with dryness and water loss.

Using 3D visual imaging technology for all-round data collection, density information is derived by synthesizing external quality characteristics and quality information.

China Intelligent Helping China's fruit industry good product, good brand.

Taiho photoelectric after nearly 3 years of fruit grader technology research and development and market verification, independent research and development production of 6GF series of intelligent fruit grader, technology to implement the current relevant standards, can be used for standardized production, through the Ministry of Agriculture and Rural Affairs of the Ministry of Agricultural Machinery Experiment and Appraisal General Station of the Ministry of promotion appraisal, and get the certificate of Agricultural Machinery Promotion Appraisal.

At present, the system has been widely used in apples, pears, oranges, lemons, kiwis and other fruit and vegetable varieties, for example, to help China's Shaanxi Province to solve the problem of fruit sorting, penetrate the whole process of the scene application, to fully meet the standardization of the fruit industry enterprises, industrialization, intelligent needs, and help to promote the development of the fruit industry from the increase in production-oriented to improve quality-oriented.

"Since the selection of Taiho 4.0 Intelligent Fruit Sorting System, the accuracy of fruit sorting has been improved, the pass rate can reach more than 95%, the fruit loss rate reaches less than 5%, which reduces the cost and improves the quality of sorting for our company" The person in charge of the Fubai Fruit Industry said that although our country is a big country in the production of fruits, but it's not a strong country in the production of fruits. In order to improve the quality of fruit processing and product grade, the need for strict quality grading and size grading of fruit.

In 2007, rich hundred fruit industry limited company was identified as the country's only use of "China women's volleyball team special supply apple" logo of the enterprise. 2008, for the Beijing Olympic Games after the special supply of apples, general manager Li Jindou has been thinking about a problem: how to better play the brand effect, quality and quantity of supply, the company's industrial technological innovation, has been The company's industrial technology innovation has been imperative.

In order to better improve the quality of apples and maximize the brand effect, Fubai Fruit Industry introduced Taiho Photoelectric Intelligent Fruit Grading System in 2016.

6GF series intelligent fruit grading machine is independently developed and manufactured by Taiho Optoelectronics, which adopts for the first time the non-destructive air-drying and conveying technology of fruits, omni-directional multi-viewing angle vision technology, infrared identification dark injury technology, relying on Taiho Optoelectronics many years of accumulation of artificial intelligence sorting technology, cloud identification sorting technology and many other core technologies, omni-directional data collection and high-speed information processing, realizing the shape selection, color selection, quality selection (sugar, acidity Intelligent sorting (sugar, acidity). The results of grading and classification are clearly displayed, the product structure is reasonable, the system configuration meets the needs of the fruit industry, the degree of automation is high, and it is easy to learn and use.

Internal Quality Inspection

Infrared identification of dark injury technology, detection of sugar content, mold heart disease and other internal physiological indicators.

The sample model established by adopting the fully transmissive detection technology and the new dynamic modeling method is more real and effective, and at the same time, it applies the multi-dimensional model coupling algorithm and the neural network algorithm, and is the first one to use the big data and the deep learning method to optimize the model continuously.

Appearance Quality Inspection

Omni-directional multi-view vision technology to detect fruit shape, color, defects and other external quality indicators.

Multiple high-resolution industrial camera lenses, with special LED light source system for all-round data acquisition, Gauss-Laplace hybrid model algorithm to solve the high-speed dynamic background target detection.

Weight Detection

Unique dynamic calibration as well as temperature compensation function to avoid measurement errors caused by environmental differences.

Single sensor and special fruit cup with four points of contact to avoid measurement errors caused by mechanical vibration problems, high-speed dynamic measurement of up to 1600 times/second, four levels of effective filtering to ensure fast detection and high accuracy of weight.

Density testing

Screens out fruits with dryness and water loss.

Using 3D visual imaging technology for all-round data collection, density information is derived by synthesizing external quality characteristics and quality information.

China Intelligent Helping China's fruit industry good product, good brand.

Taiho photoelectric after nearly 3 years of fruit grader technology research and development and market verification, independent research and development production of 6GF series of intelligent fruit grader, technology to implement the current relevant standards, can be used for standardized production, through the Ministry of Agriculture and Rural Affairs of the Ministry of Agricultural Machinery Experiment and Appraisal General Station of the Ministry of promotion appraisal, and get the certificate of Agricultural Machinery Promotion Appraisal.

At present, the system has been widely used in apples, pears, oranges, lemons, kiwis and other fruit and vegetable varieties, for example, to help China's Shaanxi Province to solve the problem of fruit sorting, penetrate the whole process of the scene application, to fully meet the standardization of the fruit industry enterprises, industrialization, intelligent needs, and help to promote the development of the fruit industry from the increase in production-oriented to improve quality-oriented.