Industrial Robotics in the Context of the "New Infrastructure"

Release Date:2020-05-30 Source: Number of views:1041

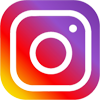

Recently, CCTV - CCTV International Chinese Channel "officially announced" the "new infrastructure" involves seven major areas, giving the definition of "to develop in the science and technology section of infrastructure construction, providing a new impetus for economic growth". infrastructure construction, providing a new impetus for economic growth".

Taking the industrial Internet as an example, the new infrastructure and traditional infrastructure are inseparable, mainly to meet the needs of serving the high-quality development of the economy and replenishing the short board. We can see more and more enterprises, both Chinese and foreign enterprises are carrying out intelligent, networked, digital transformation, through the three to improve the quality of products and business efficiency, which is behind the huge role played by the industrial Internet.

Industrial robots in the context of the "new infrastructure".

The importance of artificial intelligence cannot be overstated. But industrial robots have also become an important player in the process of transformation and upgrading of the manufacturing army. Their mechanical arms are not limited by time and harsh environments, and they can replace human labor under program control, and are able to flexibly carry out a variety of complex production tasks. Among them, palletizing robots are not only able to accurately, efficiently, stably and flexibly complete the palletizing work and improve the quality of palletizing, but also save the cost of manual palletizing for enterprises to a certain extent.

Palletizing robot is a product of the organic combination of machinery and artificial intelligence, its core role is to replace manual realization of automatic palletizing of workpieces at the end of the production line, and more and more enterprises are adopting personalized customized production mode, which makes large-scale and batch manufacturing more flexible and smarter. Promote the industry to be more networked and digitalized, which cannot be adapted by traditional equipment and can only be completed by palletizing robots.

The establishment of intelligent warehousing and the development of smart factories and the weakening of the demographic dividend will bring the large-scale application of palletizing robots, the market size and sales will maintain rapid growth, enterprises want to grow and develop, we must be driven by technological innovation, based on the information network for high-quality development needs to carry out the digital transformation, intelligent upgrading, convergence of innovations and other to enhance the comprehensive strength, so as to occupy a dominant position in the market.

Palletizing robots inject "catalyst" for economic development

According to the data, the sales of palletizing robots in 2017 was about 43,000 units, a year-on-year growth of 33%. In the future, it is expected that the market size is expected to reach 16.6 billion yuan in 2020, and market sales may reach 110,000 units. In recent years, the advantages of palletizing robots have become increasingly prominent, and application scenarios have been broadened in various industries.

Palletizing Robots for Industrial Intelligent Manufacturing Obvious Advantages

Palletizing robot is one of the mechanical equipments with high degree of automation at present, with flexible and precise movements, fast and efficient, high stability, and capable of replacing people in high-intensity palletizing operations.

Traditional manual handling palletizing, employee labor intensity, low productivity, and difficult to operate, difficult to train, and intelligent palletizing robot one of the biggest advantages is to liberate the labor force, a palletizing machine can replace the workload of at least three or four workers, improve labor efficiency.

With the development of artificial intelligence, big data, sensors, machine vision and other information technology, machine learning and other artificial intelligence algorithms iterative optimization is constantly accelerating, in the enterprise production, the popularity of intelligent equipment is getting higher and higher, palletizing robots in the field of deepening the application of the field, greatly alleviating the production enterprises in the palletizing link of the various problems and accelerate to enhance the automation level of the entire production line.

Taiho optoelectronic palletizing robots are quick to strike with extraordinary skills

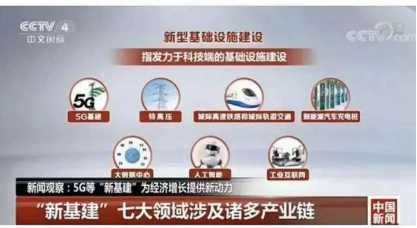

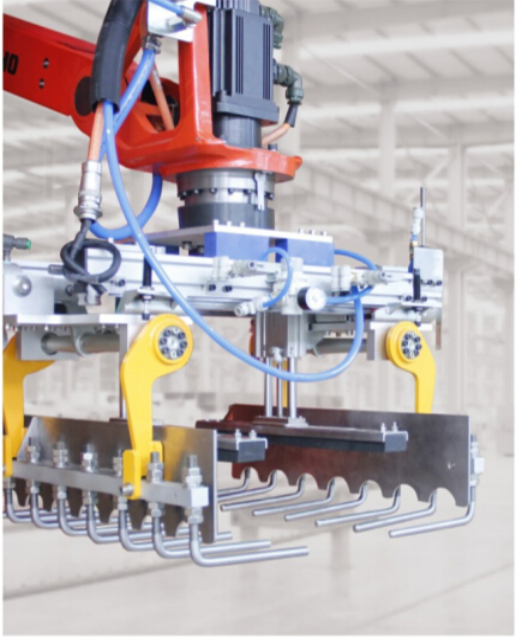

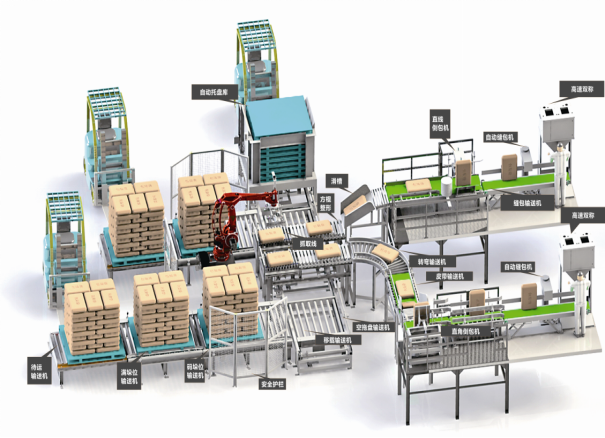

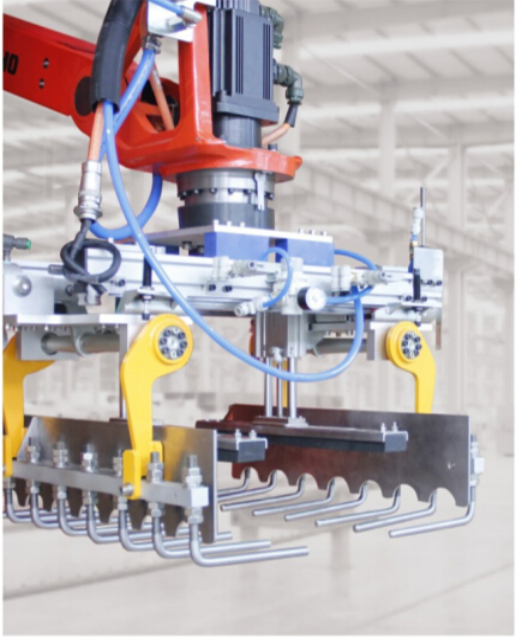

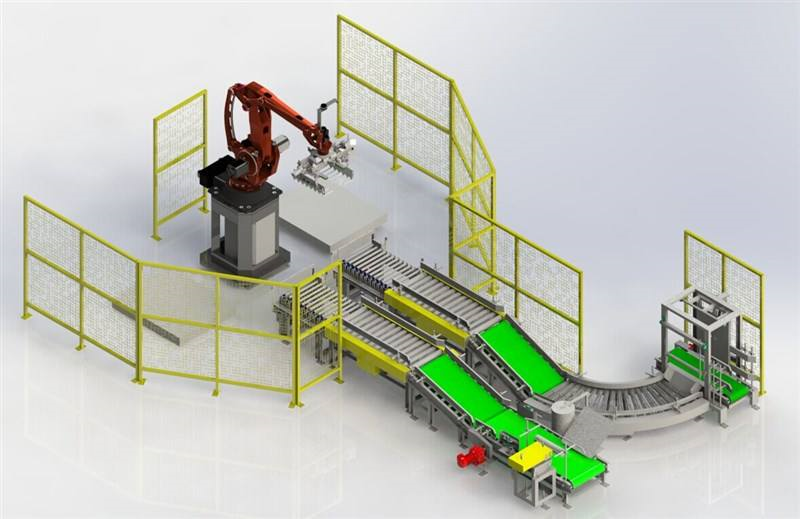

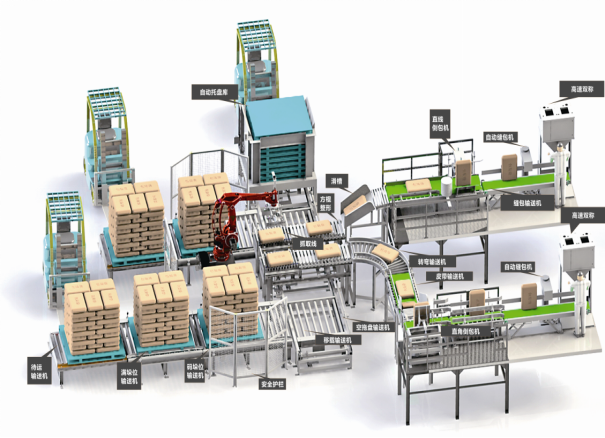

Taiho Optoelectronics palletizing robot's working system includes robot body, robot gripper, pallet conveyor, positioning equipment, as well as matching software and electrical system, etc., which can realize all kinds of palletizing operations in complex scenarios.

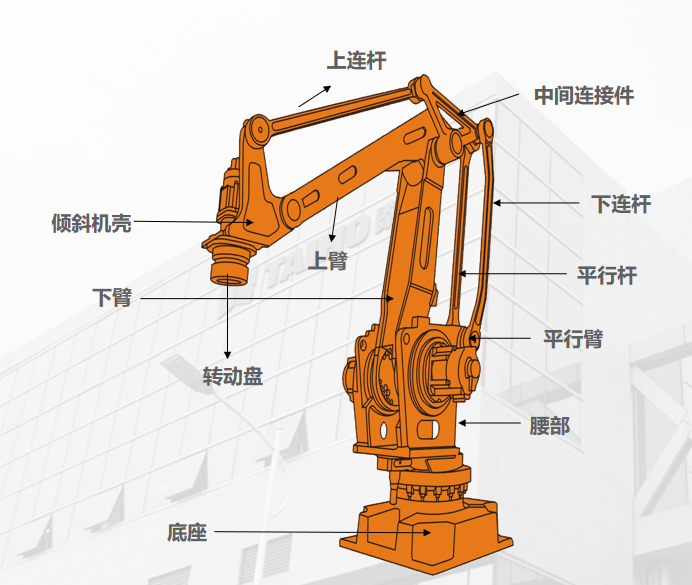

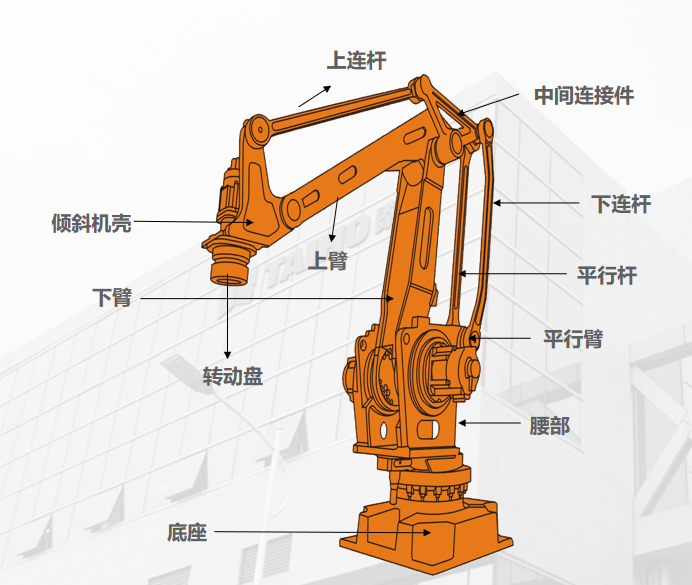

In recent years, Taiho Optronics has continued to develop and optimize its palletizing robots. In terms of the mechanical body, the base, waist, wrist and end actuator of the palletizing robot have been rectified in detail, making the mechanical structure of the robot body more reasonable and the overall sealing better. It improves the service life of the robot and its ability to prevent dust and moisture. In terms of the controller, a self-developed hardware control platform is used, which reduces the size of the controller, lowers the power consumption of the device, and improves the real-time performance of the system.

The hardware and software have been upgraded in terms of the teach pendant. The hardware upgrade makes the teach pendant more stable and operable, and it can be used for a long time and trouble-free in the harsh factory environment. The optimization of the software makes the programming and use of the oscillator a lower threshold, which is conducive to the convenient and quick operation of the workers.

Nowadays, smart factory is a strategic direction to lead the scientific and technological revolution and industrial change, and it is an important strategic resource to promote the development of China's manufacturing industry, industrial optimization and upgrading, and the overall leap in productivity. And Taiho photoelectric palletizing robot, as a representative of the development of smart factory, has become a pusher of industrial intelligent transformation in the application practice of various industries.

Recently, CCTV - CCTV International Chinese Channel "officially announced" the "new infrastructure" involves seven major areas, giving the definition of "to develop in the science and technology section of infrastructure construction, providing a new impetus for economic growth". infrastructure construction, providing a new impetus for economic growth".

Taking the industrial Internet as an example, the new infrastructure and traditional infrastructure are inseparable, mainly to meet the needs of serving the high-quality development of the economy and replenishing the short board. We can see more and more enterprises, both Chinese and foreign enterprises are carrying out intelligent, networked, digital transformation, through the three to improve the quality of products and business efficiency, which is behind the huge role played by the industrial Internet.

Industrial robots in the context of the "new infrastructure".

The importance of artificial intelligence cannot be overstated. But industrial robots have also become an important player in the process of transformation and upgrading of the manufacturing army. Their mechanical arms are not limited by time and harsh environments, and they can replace human labor under program control, and are able to flexibly carry out a variety of complex production tasks. Among them, palletizing robots are not only able to accurately, efficiently, stably and flexibly complete the palletizing work and improve the quality of palletizing, but also save the cost of manual palletizing for enterprises to a certain extent.

Palletizing robot is a product of the organic combination of machinery and artificial intelligence, its core role is to replace manual realization of automatic palletizing of workpieces at the end of the production line, and more and more enterprises are adopting personalized customized production mode, which makes large-scale and batch manufacturing more flexible and smarter. Promote the industry to be more networked and digitalized, which cannot be adapted by traditional equipment and can only be completed by palletizing robots.

The establishment of intelligent warehousing and the development of smart factories and the weakening of the demographic dividend will bring the large-scale application of palletizing robots, the market size and sales will maintain rapid growth, enterprises want to grow and develop, we must be driven by technological innovation, based on the information network for high-quality development needs to carry out the digital transformation, intelligent upgrading, convergence of innovations and other to enhance the comprehensive strength, so as to occupy a dominant position in the market.

Palletizing robots inject "catalyst" for economic development

According to the data, the sales of palletizing robots in 2017 was about 43,000 units, a year-on-year growth of 33%. In the future, it is expected that the market size is expected to reach 16.6 billion yuan in 2020, and market sales may reach 110,000 units. In recent years, the advantages of palletizing robots have become increasingly prominent, and application scenarios have been broadened in various industries.

Palletizing Robots for Industrial Intelligent Manufacturing Obvious Advantages

Palletizing robot is one of the mechanical equipments with high degree of automation at present, with flexible and precise movements, fast and efficient, high stability, and capable of replacing people in high-intensity palletizing operations.

Traditional manual handling palletizing, employee labor intensity, low productivity, and difficult to operate, difficult to train, and intelligent palletizing robot one of the biggest advantages is to liberate the labor force, a palletizing machine can replace the workload of at least three or four workers, improve labor efficiency.

With the development of artificial intelligence, big data, sensors, machine vision and other information technology, machine learning and other artificial intelligence algorithms iterative optimization is constantly accelerating, in the enterprise production, the popularity of intelligent equipment is getting higher and higher, palletizing robots in the field of deepening the application of the field, greatly alleviating the production enterprises in the palletizing link of the various problems and accelerate to enhance the automation level of the entire production line.

Taiho optoelectronic palletizing robots are quick to strike with extraordinary skills

Taiho Optoelectronics palletizing robot's working system includes robot body, robot gripper, pallet conveyor, positioning equipment, as well as matching software and electrical system, etc., which can realize all kinds of palletizing operations in complex scenarios.

In recent years, Taiho Optronics has continued to develop and optimize its palletizing robots. In terms of the mechanical body, the base, waist, wrist and end actuator of the palletizing robot have been rectified in detail, making the mechanical structure of the robot body more reasonable and the overall sealing better. It improves the service life of the robot and its ability to prevent dust and moisture. In terms of the controller, a self-developed hardware control platform is used, which reduces the size of the controller, lowers the power consumption of the device, and improves the real-time performance of the system.

The hardware and software have been upgraded in terms of the teach pendant. The hardware upgrade makes the teach pendant more stable and operable, and it can be used for a long time and trouble-free in the harsh factory environment. The optimization of the software makes the programming and use of the oscillator a lower threshold, which is conducive to the convenient and quick operation of the workers.

Nowadays, smart factory is a strategic direction to lead the scientific and technological revolution and industrial change, and it is an important strategic resource to promote the development of China's manufacturing industry, industrial optimization and upgrading, and the overall leap in productivity. And Taiho photoelectric palletizing robot, as a representative of the development of smart factory, has become a pusher of industrial intelligent transformation in the application practice of various industries.