Under the impact of the epidemic, in the face of rising labor costs, how to achieve cost reduction and efficiency of enterprises

Release Date:2021-01-19 Source: Number of views:963

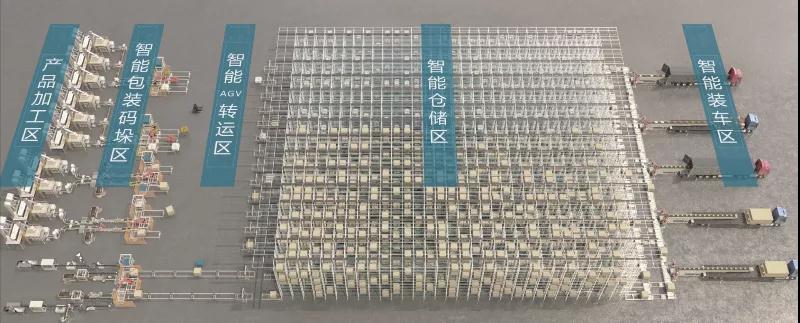

During the recurrence of the epidemic, due to the epidemic control needs, around the implementation of the staggered holiday, local New Year's Eve, isolation and other policies, the labor requirements of the industry and enterprises have been affected by the greater, on the contrary, the high degree of mechanization, the need for less labor, easy to control intelligent factories have become a major bright spot.

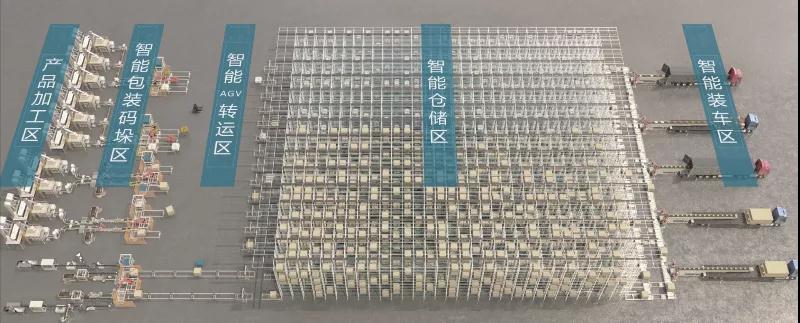

Intelligent factories apply intelligent equipment and facilities such as AI sorting, intelligent packaging, intelligent loading, etc., to minimize the energy that people need to put in and the understanding required by digitizing the tedious work or calling guidance directly to work based on datatization.

In this context, based on the unmanned, less manned cargo loading scenarios will have a greater development, the demand for intelligent loading technology to match will also increase, the depth of the application of intelligent loading technology and reliability have higher requirements. At the same time, 5G-based commercial applications will promote the realization of various industries based on the "Internet of Things + Artificial Intelligence" smart factory model transformation, vehicle, cargo, warehouse truly interconnected interaction, accelerate the realization of factory intelligence.

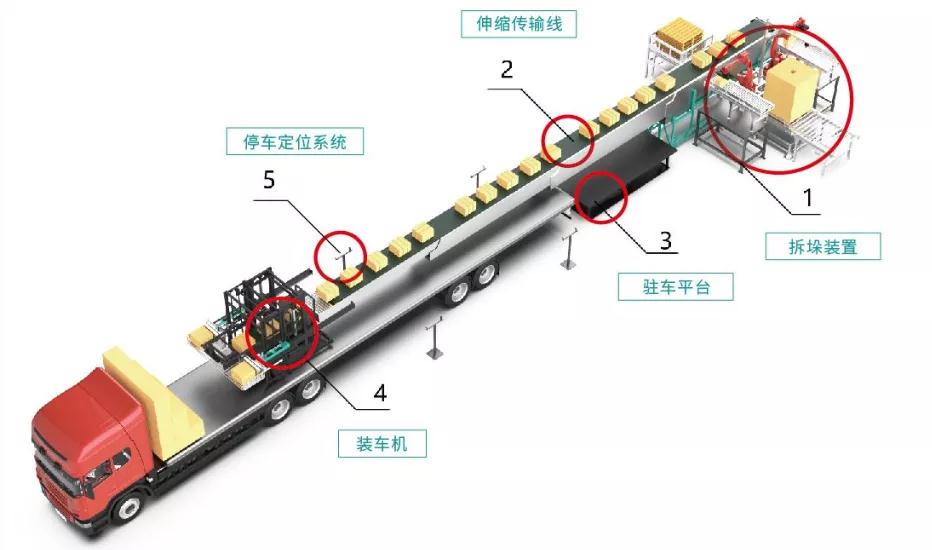

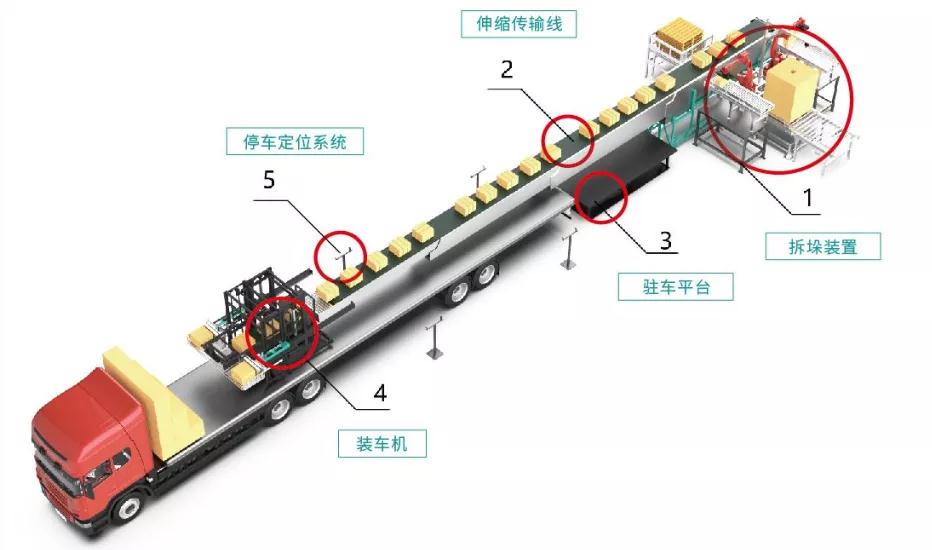

Taiho intelligent loading system provides enterprises with automation, informationization, intelligent cargo loading overall solution. Intelligent loading system includes depalletizing mechanism, conveying mechanism, loading mechanism as well as intelligent management software, numerical simulation system and other intelligent equipments and software, which can depalletize, sort and convey the goods to the loading machine, and then yard the goods to the trucks through the loading machine. The whole workflow does not require workers to operate, avoiding the problems of labor scarcity and high employment cost, and at the same time greatly reducing the safety hazards of the enterprise.

(Intelligent loading system)

Intelligent loading system not only realizes the unmanned operation of depalletizing and loading, but also its numerical simulation system improves the scheduling intelligence and loading efficiency of the storage and transportation process for enterprises. The numerical simulation system can simulate the loading workflow, such as the sequence of depalletizing, depalletizing robot work beat, conveying speed, etc. Through simulation, it can optimize the design parameters and workflow, improve the loading efficiency, and reduce the cost and increase the efficiency of the enterprise in an optimal way.

(3D simulation of intelligent loading process)

Epidemic is order, prevention and control is responsibility. Taiho intelligent loading system provides automation, informatization and intelligent cargo loading solution for the production enterprises under the repeated epidemic, which fundamentally solves the problems of labor reduction and safety hazards of the enterprises.

During the recurrence of the epidemic, due to the epidemic control needs, around the implementation of the staggered holiday, local New Year's Eve, isolation and other policies, the labor requirements of the industry and enterprises have been affected by the greater, on the contrary, the high degree of mechanization, the need for less labor, easy to control intelligent factories have become a major bright spot.

Intelligent factories apply intelligent equipment and facilities such as AI sorting, intelligent packaging, intelligent loading, etc., to minimize the energy that people need to put in and the understanding required by digitizing the tedious work or calling guidance directly to work based on datatization.

In this context, based on the unmanned, less manned cargo loading scenarios will have a greater development, the demand for intelligent loading technology to match will also increase, the depth of the application of intelligent loading technology and reliability have higher requirements. At the same time, 5G-based commercial applications will promote the realization of various industries based on the "Internet of Things + Artificial Intelligence" smart factory model transformation, vehicle, cargo, warehouse truly interconnected interaction, accelerate the realization of factory intelligence.

Taiho intelligent loading system provides enterprises with automation, informationization, intelligent cargo loading overall solution. Intelligent loading system includes depalletizing mechanism, conveying mechanism, loading mechanism as well as intelligent management software, numerical simulation system and other intelligent equipments and software, which can depalletize, sort and convey the goods to the loading machine, and then yard the goods to the trucks through the loading machine. The whole workflow does not require workers to operate, avoiding the problems of labor scarcity and high employment cost, and at the same time greatly reducing the safety hazards of the enterprise.

(Intelligent loading system)

Intelligent loading system not only realizes the unmanned operation of depalletizing and loading, but also its numerical simulation system improves the scheduling intelligence and loading efficiency of the storage and transportation process for enterprises. The numerical simulation system can simulate the loading workflow, such as the sequence of depalletizing, depalletizing robot work beat, conveying speed, etc. Through simulation, it can optimize the design parameters and workflow, improve the loading efficiency, and reduce the cost and increase the efficiency of the enterprise in an optimal way.

(3D simulation of intelligent loading process)

Epidemic is order, prevention and control is responsibility. Taiho intelligent loading system provides automation, informatization and intelligent cargo loading solution for the production enterprises under the repeated epidemic, which fundamentally solves the problems of labor reduction and safety hazards of the enterprises.