Industry | Say goodbye to the "lack of labor" to make "handling" easier, intelligent loading wind mouth is approaching

Release Date:2021-01-29 Source: Number of views:986

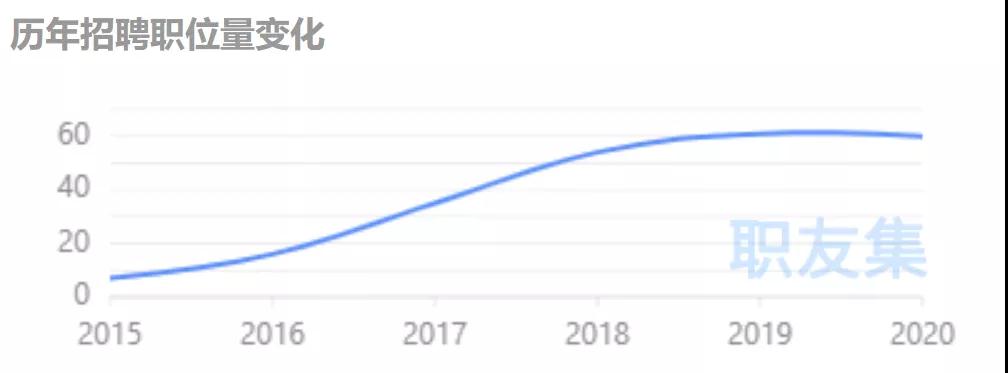

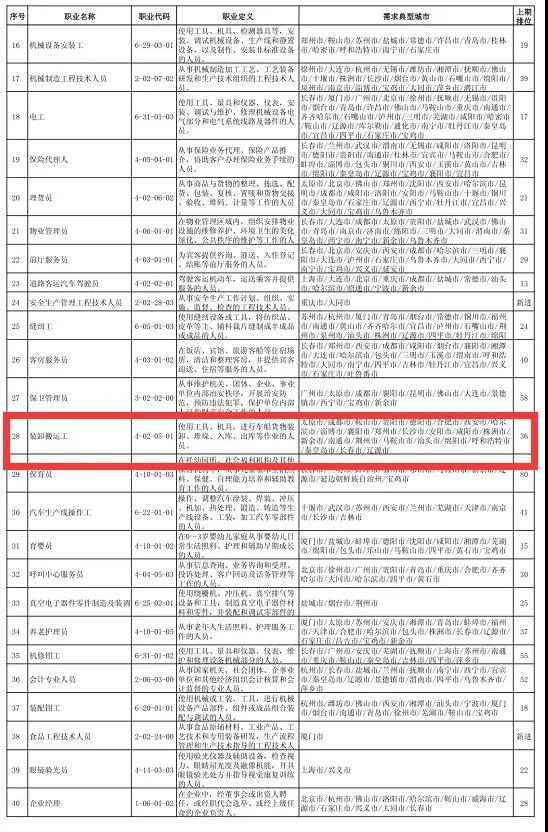

The Bureau of Human Resources and Social Security released in the fourth quarter of 2020, the national recruitment is greater than the job search "the most short of labor" in the ranking of the 100 occupations, loading and unloading porters ranked 28th, becoming the enterprise "the most short of labor", which brings unprecedented huge pressure on manufacturing enterprises.

Difficulty in recruiting expensive labor phenomenon intensified, industrial transformation is imminent

The period of abundant labor force of the right age brought about by the peak of fertility in China has passed, and the demographic structure has begun to change, in which the largest proportion of the population aged 35-40 and 40-44 are 9.1% and 9.6% respectively, and the proportion of the remaining working population aged 15-34 ranges from 6-7%, with a gradual trend of shrinkage. The gradual decline in labor supply has led to a shortage of labor and rising costs, and the problem of labor shortage will become more and more serious in the future.

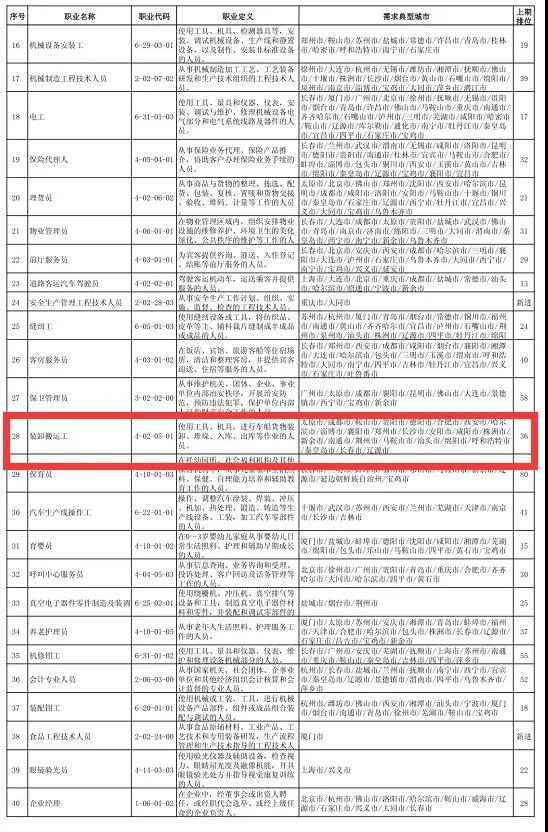

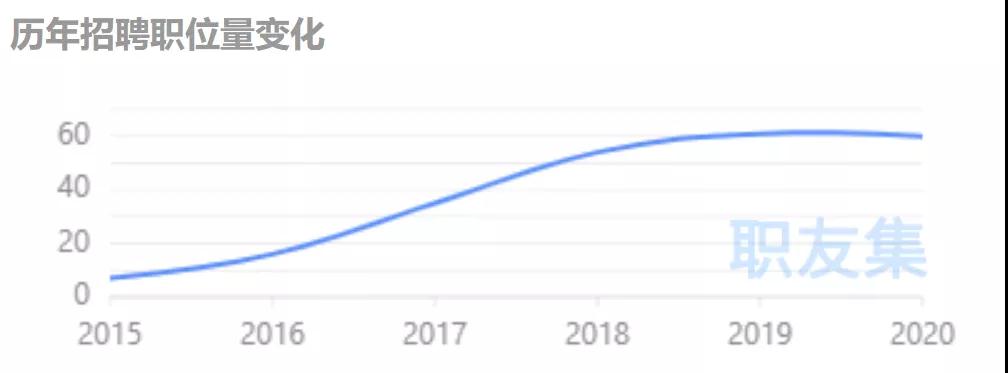

(Changes in the number of jobs filled by loaders and unloaders over the years)

Currently, most of the jobs offered by China's manufacturing sector are low-paying and low-skilled, and generally only young people with low levels of education are willing to take them on. However, as the education level of China's younger generation rises, the proportion of those willing to take up low-paying, low-skilled jobs decreases, so the labor shortage in China's grass-roots manufacturing sector is not only the result of a declining youth population. The fact that the young population does not want to work in low-ranking manufacturing and prefers to enter the service sector is also an important reason for the labor shortage.

The reluctance of the post-90s to enter factories has made it more difficult for companies to recruit a young and strong labor force, and when they do, they find that the situation presented is a dual problem of rising salary costs and the increasing age of porters.

(Length of service of stevedores and changes in wages over the years)

From the point of view of the social environment and labor costs, it is a trend for enterprises to carry out intelligent and digital transformation, which can solve the phenomenon of "labor shortage" and reduce costs while increasing profits.

Comparative advantage in labor costs is gone, and industrial habitats are facing rearrangement

Employment dilemma has given rise to the "smart factory" boom. For manufacturing enterprises, high labor costs and recruitment difficulties are significant pressures, which have a greater impact on the sustainable development and profitability of enterprises. In such a situation, some labor-intensive enterprises take the lead in introducing automation equipment to replace manual labor, and gradually increase the scale of application of intelligent and automated equipment.

In order to create a "smart factory", to solve the "labor shortage", many enterprises have been planning to intelligent loading system applied to the field of warehousing, to achieve unmanned production and storage and transportation, full automation, to achieve a complete "closed loop" of the smart factory! ".

Replacing manual labor with technology to liberate traditional labor

Taiho's intelligent loading system automatically identifies, depalletizes and picks the goods through depalletizing robots, transfers the goods to the corresponding target shipping area, and then through the automatic loading robots in the shipping area, the goods are regularized and stacked in the wagon compartment, and finally transported to the customer's terminal, creating a seamless connection. Factories and warehouses achieve efficiency and accuracy far beyond manual labor, the core of which lies in the intelligent loading system that acts as a flexible interface between warehouse terminals and trucks for the original manual workstations.

The role of flexible interfaces is to achieve flexible connections and flexibilization. The individualized and differentiated needs of end customers require diversified product loading out of the warehouse, and flexibility allows the loading line to have the ability to load diversified products; in addition, flexibility also improves the timeliness of the storage and transportation process in response to the supply chain.

(Taihe Intelligent Loading System)

Taiho intelligent system can flexibly configure and adjust the production elements to improve the speed of product handling, which can be operated efficiently and stably over a long period of time to realize the loading of multi-batches and customized products, and complete the workflow of acquiring tasks - depalletizing - scanning - loading.

The Bureau of Human Resources and Social Security released in the fourth quarter of 2020, the national recruitment is greater than the job search "the most short of labor" in the ranking of the 100 occupations, loading and unloading porters ranked 28th, becoming the enterprise "the most short of labor", which brings unprecedented huge pressure on manufacturing enterprises.

Difficulty in recruiting expensive labor phenomenon intensified, industrial transformation is imminent

The period of abundant labor force of the right age brought about by the peak of fertility in China has passed, and the demographic structure has begun to change, in which the largest proportion of the population aged 35-40 and 40-44 are 9.1% and 9.6% respectively, and the proportion of the remaining working population aged 15-34 ranges from 6-7%, with a gradual trend of shrinkage. The gradual decline in labor supply has led to a shortage of labor and rising costs, and the problem of labor shortage will become more and more serious in the future.

(Changes in the number of jobs filled by loaders and unloaders over the years)

Currently, most of the jobs offered by China's manufacturing sector are low-paying and low-skilled, and generally only young people with low levels of education are willing to take them on. However, as the education level of China's younger generation rises, the proportion of those willing to take up low-paying, low-skilled jobs decreases, so the labor shortage in China's grass-roots manufacturing sector is not only the result of a declining youth population. The fact that the young population does not want to work in low-ranking manufacturing and prefers to enter the service sector is also an important reason for the labor shortage.

The reluctance of the post-90s to enter factories has made it more difficult for companies to recruit a young and strong labor force, and when they do, they find that the situation presented is a dual problem of rising salary costs and the increasing age of porters.

(Length of service of stevedores and changes in wages over the years)

From the point of view of the social environment and labor costs, it is a trend for enterprises to carry out intelligent and digital transformation, which can solve the phenomenon of "labor shortage" and reduce costs while increasing profits.

Comparative advantage in labor costs is gone, and industrial habitats are facing rearrangement

Employment dilemma has given rise to the "smart factory" boom. For manufacturing enterprises, high labor costs and recruitment difficulties are significant pressures, which have a greater impact on the sustainable development and profitability of enterprises. In such a situation, some labor-intensive enterprises take the lead in introducing automation equipment to replace manual labor, and gradually increase the scale of application of intelligent and automated equipment.

In order to create a "smart factory", to solve the "labor shortage", many enterprises have been planning to intelligent loading system applied to the field of warehousing, to achieve unmanned production and storage and transportation, full automation, to achieve a complete "closed loop" of the smart factory! ".

Replacing manual labor with technology to liberate traditional labor

Taiho's intelligent loading system automatically identifies, depalletizes and picks the goods through depalletizing robots, transfers the goods to the corresponding target shipping area, and then through the automatic loading robots in the shipping area, the goods are regularized and stacked in the wagon compartment, and finally transported to the customer's terminal, creating a seamless connection. Factories and warehouses achieve efficiency and accuracy far beyond manual labor, the core of which lies in the intelligent loading system that acts as a flexible interface between warehouse terminals and trucks for the original manual workstations.

The role of flexible interfaces is to achieve flexible connections and flexibilization. The individualized and differentiated needs of end customers require diversified product loading out of the warehouse, and flexibility allows the loading line to have the ability to load diversified products; in addition, flexibility also improves the timeliness of the storage and transportation process in response to the supply chain.

(Taihe Intelligent Loading System)

Taiho intelligent system can flexibly configure and adjust the production elements to improve the speed of product handling, which can be operated efficiently and stably over a long period of time to realize the loading of multi-batches and customized products, and complete the workflow of acquiring tasks - depalletizing - scanning - loading.