Taiho Case | Anhui Fengle Agrochemical Co.

Release Date:2020-04-15 Source: Number of views:1029

"In and out of the goods quickly and conveniently, reducing the intensity of human labor, improve work efficiency, and realize the first-in-first-out," said Sun, the production department minister of Anhui Fengle Agrochemical Co.

Enterprise innovation is imminent

As a matter of fact, Taiho Optoelectronics has brought more than just these innovations to Anhui Fengle.

As a large-scale state-owned enterprise founded in 1988, Anhui Fengle is mainly engaged in the integrated production and operation of seed, medicine and fertilizer, which ranks among the top 50 in the industry and has been maintaining a high level of production technology and a perfect quality management system and service system.

But with the large-scale production parks, large logistics and warehousing parks, etc. for intelligence, information technology, visualization, integration requirements are becoming higher and higher, the chairman of the board of directors that intelligence is becoming more and more an urgent problem to be solved by the company. It is very difficult to maintain the high level of production technology and guarantee the quality and service only by manual labor.

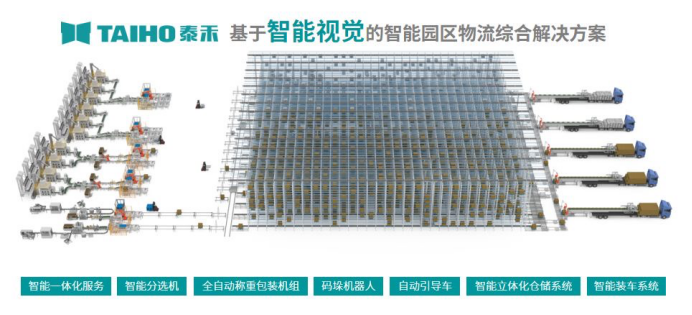

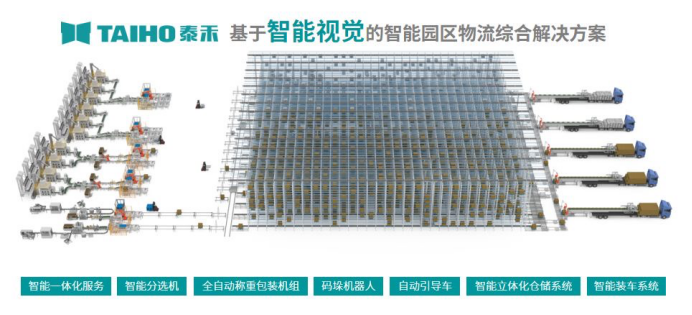

Intelligent Park Logistics Solution World Premiere

In order to develop the enterprise, it is necessary to introduce more efficient solutions, Anhui Fengle found Taiho Optoelectronics, which also coincides with Taiho Optoelectronics as the world's leading integrated solution provider of intelligent park logistics, with products covering a variety of applications such as intelligent sorting, automatic packaging, automatic palletizing, AGV intelligent transportation, intelligent warehousing, automatic loading, and intelligent vision of the machine, etc. Taiho Optoelectronics is a leading supplier of intelligent park logistics solutions for the park to build a "smart factory". For the park to create a "smart factory" to achieve production, packaging, palletizing, transportation, warehousing, logistics and other multi-dimensional automation management.

Seeing such a comprehensive intelligent park logistics integrated solutions, more firmly the determination of Anhui Fengle seed industry to intelligent park logistics.

After many comparisons, Anhui Fengle finally chose Taiho Optoelectronics and reached project cooperation.

Machine for man Reduce energy consumption

Before using Taiho photoelectric palletizing robot, Anhui Fengle adopts manual handling palletizing, the staff labor intensity, low productivity, and difficult to operate, difficult to train, and Taiho photoelectric intelligent palletizing robot one of the biggest advantages is to liberate the labor force, a palletizing machine can at least replace the workload of three or four workers, improve labor efficiency. And the energy consumption of palletizing robot is very low, the power is about 5KW.

The palletizing line is a fully automated assembly line that greatly reduces product damage.

For different specifications of bags or boxes gripping accurate, high precision, fast speed, can be gripped, working radius up to 2350mm, the maximum load of up to 120KG, positioning accuracy of up to ± 0.1mm, man-machine interaction interface is simple and friendly, easy to operate, easy to use.

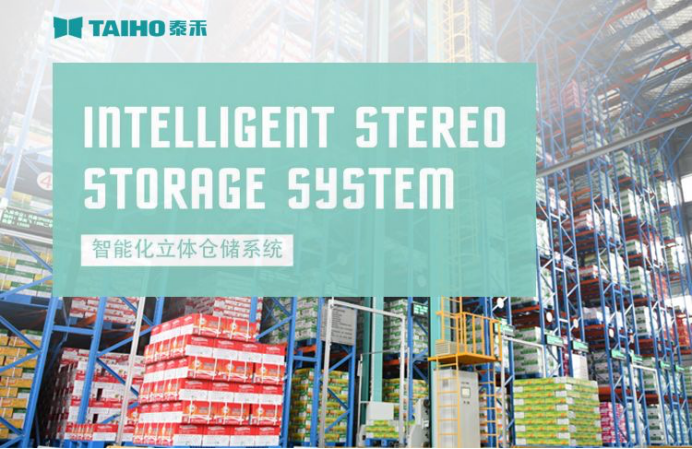

The introduction of intelligent park logistics integrated solutions also includes Taiho Optronics intelligent three-dimensional warehousing system.

Warehousing costs and logistics costs have been one of the biggest costs of Anhui Fengle, traditional warehouse personnel needs more, labor costs, slow shipping efficiency, space limitations (generally the highest height of 15 meters), cargo damage is relatively serious (stolen, inbound and outbound cargo damage), the amount of large warehouse hours need to rent outside the warehouse, transit costs are high, cargo damage is serious. In the face of these problems, Taiho photoelectric intelligent warehousing system utilizes automation, AGV automatic forklift, intelligent robots and automatic warehousing technology to realize unmanned intelligent automated warehouse management, reduce the warehouse floor space, speed up the speed of access to materials and reduce the cost of warehousing.

Taiho photoelectric intelligent three-dimensional warehousing system consists of inlet and outlet conveying system, high-level shelves, alley-type stacker cranes, and control system to form the core of the system. Supporting power supply system, air-conditioning system, fire alarm system, weighing and measuring system, packaging system and network communication system, it creates a more efficient and flexible internal logistics system for Anhui Fengle.

collaborate Creating a "smart factory"

Taiho Optoelectronics intelligent park logistics solution solves the problems of manpower, cost and environmental protection of Anhui Fengle from multi-dimension, and meets the enterprise's modern digital, networked and intelligent production needs.

Mr. Meng said, "Since the introduction of Taiho's intelligent park logistics solution, it has reduced the difficulty of logistics and warehouse management in the park, facilitated the operation process, saved the management cost, and improved the economic benefits, and in the future, we will continue to choose Taiho's products, and continue to maintain the cooperation."

In the era of Intelligent Intelligent Manufacturing Industry 4.0, Taiho Optoelectronics has no choice but to take on the social responsibility and provide scientific and technological support for the enterprise. In the future, Taiho Optoelectronics will increase the investment in innovation, promote the change of management, and take the customer experience as the primary criterion, and strive to provide customers with all-around, personalized and professional products and services.

"In and out of the goods quickly and conveniently, reducing the intensity of human labor, improve work efficiency, and realize the first-in-first-out," said Sun, the production department minister of Anhui Fengle Agrochemical Co.

Enterprise innovation is imminent

As a matter of fact, Taiho Optoelectronics has brought more than just these innovations to Anhui Fengle.

As a large-scale state-owned enterprise founded in 1988, Anhui Fengle is mainly engaged in the integrated production and operation of seed, medicine and fertilizer, which ranks among the top 50 in the industry and has been maintaining a high level of production technology and a perfect quality management system and service system.

But with the large-scale production parks, large logistics and warehousing parks, etc. for intelligence, information technology, visualization, integration requirements are becoming higher and higher, the chairman of the board of directors that intelligence is becoming more and more an urgent problem to be solved by the company. It is very difficult to maintain the high level of production technology and guarantee the quality and service only by manual labor.

Intelligent Park Logistics Solution World Premiere

In order to develop the enterprise, it is necessary to introduce more efficient solutions, Anhui Fengle found Taiho Optoelectronics, which also coincides with Taiho Optoelectronics as the world's leading integrated solution provider of intelligent park logistics, with products covering a variety of applications such as intelligent sorting, automatic packaging, automatic palletizing, AGV intelligent transportation, intelligent warehousing, automatic loading, and intelligent vision of the machine, etc. Taiho Optoelectronics is a leading supplier of intelligent park logistics solutions for the park to build a "smart factory". For the park to create a "smart factory" to achieve production, packaging, palletizing, transportation, warehousing, logistics and other multi-dimensional automation management.

Seeing such a comprehensive intelligent park logistics integrated solutions, more firmly the determination of Anhui Fengle seed industry to intelligent park logistics.

After many comparisons, Anhui Fengle finally chose Taiho Optoelectronics and reached project cooperation.

Machine for man Reduce energy consumption

Before using Taiho photoelectric palletizing robot, Anhui Fengle adopts manual handling palletizing, the staff labor intensity, low productivity, and difficult to operate, difficult to train, and Taiho photoelectric intelligent palletizing robot one of the biggest advantages is to liberate the labor force, a palletizing machine can at least replace the workload of three or four workers, improve labor efficiency. And the energy consumption of palletizing robot is very low, the power is about 5KW.

The palletizing line is a fully automated assembly line that greatly reduces product damage.

For different specifications of bags or boxes gripping accurate, high precision, fast speed, can be gripped, working radius up to 2350mm, the maximum load of up to 120KG, positioning accuracy of up to ± 0.1mm, man-machine interaction interface is simple and friendly, easy to operate, easy to use.

The introduction of intelligent park logistics integrated solutions also includes Taiho Optronics intelligent three-dimensional warehousing system.

Warehousing costs and logistics costs have been one of the biggest costs of Anhui Fengle, traditional warehouse personnel needs more, labor costs, slow shipping efficiency, space limitations (generally the highest height of 15 meters), cargo damage is relatively serious (stolen, inbound and outbound cargo damage), the amount of large warehouse hours need to rent outside the warehouse, transit costs are high, cargo damage is serious. In the face of these problems, Taiho photoelectric intelligent warehousing system utilizes automation, AGV automatic forklift, intelligent robots and automatic warehousing technology to realize unmanned intelligent automated warehouse management, reduce the warehouse floor space, speed up the speed of access to materials and reduce the cost of warehousing.

Taiho photoelectric intelligent three-dimensional warehousing system consists of inlet and outlet conveying system, high-level shelves, alley-type stacker cranes, and control system to form the core of the system. Supporting power supply system, air-conditioning system, fire alarm system, weighing and measuring system, packaging system and network communication system, it creates a more efficient and flexible internal logistics system for Anhui Fengle.

collaborate Creating a "smart factory"

Taiho Optoelectronics intelligent park logistics solution solves the problems of manpower, cost and environmental protection of Anhui Fengle from multi-dimension, and meets the enterprise's modern digital, networked and intelligent production needs.

Mr. Meng said, "Since the introduction of Taiho's intelligent park logistics solution, it has reduced the difficulty of logistics and warehouse management in the park, facilitated the operation process, saved the management cost, and improved the economic benefits, and in the future, we will continue to choose Taiho's products, and continue to maintain the cooperation."

In the era of Intelligent Intelligent Manufacturing Industry 4.0, Taiho Optoelectronics has no choice but to take on the social responsibility and provide scientific and technological support for the enterprise. In the future, Taiho Optoelectronics will increase the investment in innovation, promote the change of management, and take the customer experience as the primary criterion, and strive to provide customers with all-around, personalized and professional products and services.