Successful shipment|Successful shipment of two PIDS for key projects in Ordos

Release Date:2023-03-16 Source: Number of views:1033

Successful shipment of Ordos key projects

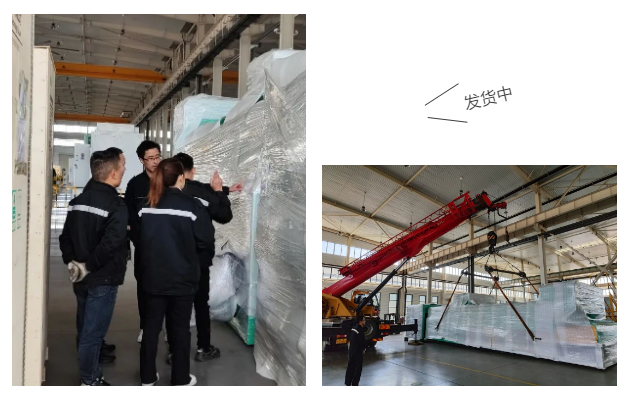

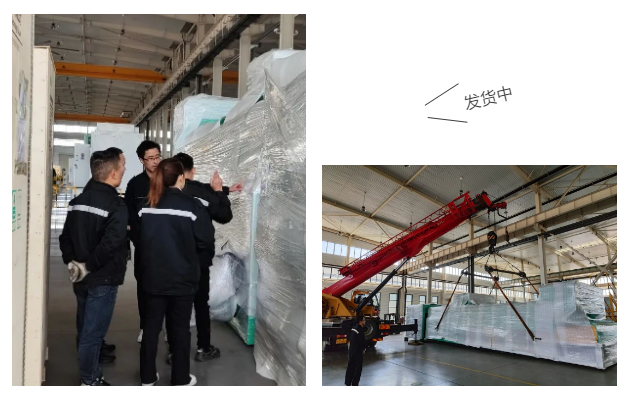

On March 14, 2 sets of PIDS belt-type intelligent dry separators were successfully sent to Ordos project site. These intelligent dry separators will greatly improve the efficiency of coal separation and reduce the cost of washing.

Straight from the shipping site progress bar

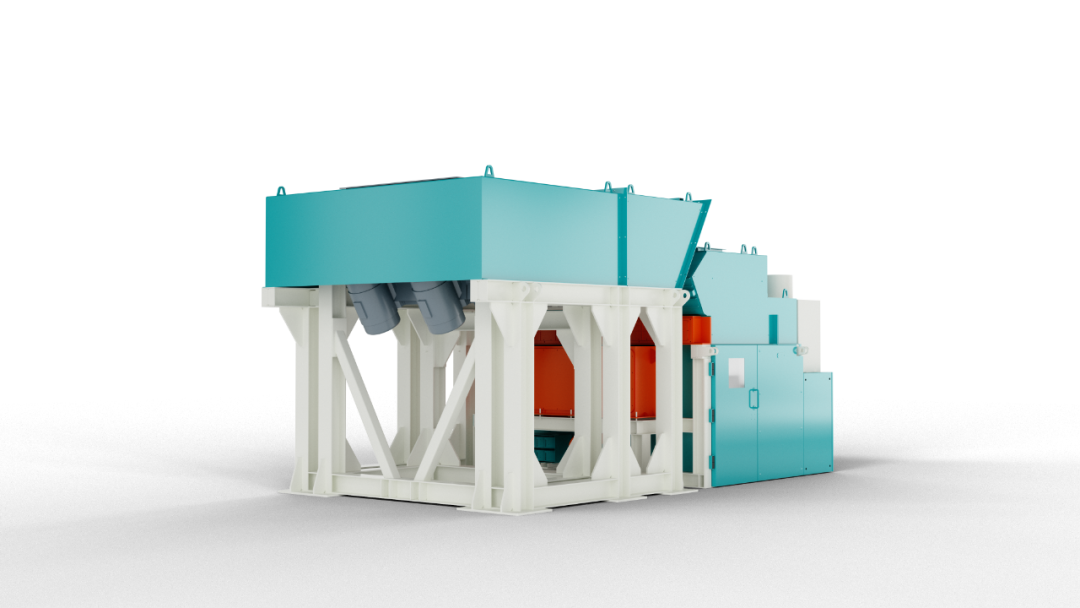

Taihe Zhuo Hai "PIDS Belt Intelligent Dry Sorting Machine" not only realizes full-automatic sorting of raw coal, but also achieves a recognition accuracy of more than 95%, overcoming environments unsuitable for traditional wet beneficiation, such as lack of water, severe cold, and easy sludging of ores, and increasing the life span and value of mines with more environmentally friendly sorting process.

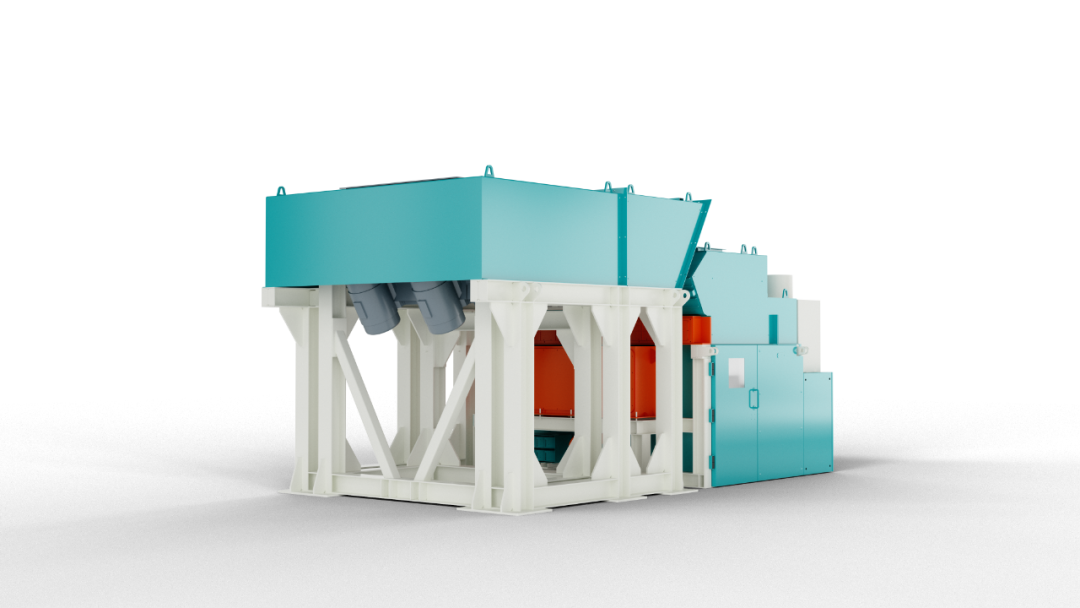

▲PIDS (grain size 25-600mm)

Taihe Zhuohai "VCS/VDS Vertical Intelligent Dry Sorting Machine" utilizes dual-energy X-ray scanning imaging system to collect the images of free-falling or chute-falling materials, with higher signal-to-noise ratio, wider adaptability to particle size, and the lower limit of the sorting particle size is as low as 6mm, and it is a dual-energy X-ray high-precision intelligent dry sorting equipment in the industry. There is no physical contact with the material throughout the whole process, so there is no risk of mechanical failure; the blowing system is arranged horizontally, so it is not easy to be blocked. Under the same conditions, the processing capacity is 30% higher than the belt-type intelligent dry separator.

▲VDS (grain size 6-200mm)

Successful shipment of Ordos key projects

On March 14, 2 sets of PIDS belt-type intelligent dry separators were successfully sent to Ordos project site. These intelligent dry separators will greatly improve the efficiency of coal separation and reduce the cost of washing.

Straight from the shipping site progress bar

Taihe Zhuo Hai "PIDS Belt Intelligent Dry Sorting Machine" not only realizes full-automatic sorting of raw coal, but also achieves a recognition accuracy of more than 95%, overcoming environments unsuitable for traditional wet beneficiation, such as lack of water, severe cold, and easy sludging of ores, and increasing the life span and value of mines with more environmentally friendly sorting process.

▲PIDS (grain size 25-600mm)

Taihe Zhuohai "VCS/VDS Vertical Intelligent Dry Sorting Machine" utilizes dual-energy X-ray scanning imaging system to collect the images of free-falling or chute-falling materials, with higher signal-to-noise ratio, wider adaptability to particle size, and the lower limit of the sorting particle size is as low as 6mm, and it is a dual-energy X-ray high-precision intelligent dry sorting equipment in the industry. There is no physical contact with the material throughout the whole process, so there is no risk of mechanical failure; the blowing system is arranged horizontally, so it is not easy to be blocked. Under the same conditions, the processing capacity is 30% higher than the belt-type intelligent dry separator.

▲VDS (grain size 6-200mm)