[Taihe Zhuohai Successfully Obtained the Intelligent Dry Selection Project of Zhangbei Coal Processing Plant of Huainan Mining Group Coal Processing Branch Company

Release Date:2023-06-12 Source: Number of views:1215

Recently, Taihe Zhuo Hai successfully won the bidding of Zhangbei Coal Beneficiation Plant Intelligent Dry Selection Project of Huainan Mining Group Coal Beneficiation Branch.

The PIDS Belt Intelligent Dry Separation Equipment of Zhangbei Coal Processing Plant, which won the bid, is the fifth project between Taihe Zhuo Hai and Huainan Mining Group after Ordos Tangjiahui Project, Huainan Zhangji Project, Guqiao Project and Xieqiao Project. Among them, Huainan Zhangji Intelligent Dry Separation Project was put into operation at the beginning of 2021, up to now, the operation is very stable, and the proportion of coal in the gangue has decreased from 8% to less than 3%, which increases the income of the enterprise by more than 5 million RMB every year, and other projects are also in stable operation.

The winning bid of intelligent dry sorting equipment of Zhangbei Coal Processing Plant will further promote the comprehensive and deep friendly cooperation between Taihe Zhuohai and Huainan Mining Group, and also marks the further development of Taihe Zhuohai's coal intelligent dry sorting market in Anhui Province, and continues to remain at the forefront of the field of intelligent dry sorting of coal and provide intelligent equipment and services for the automation and intelligent upgrading of the mines and other industries, and improve the life span of the mines with a greener and more environmentally friendly sorting process and value.

PIDS Belt Intelligent Dry Sorting Machine utilizes dual-energy X-ray/visible full-spectrum multispectral scanning imaging system to collect images of materials on the conveyor belt, analyzes the images and determines the type of materials through deep learning image recognition technology, and accurately controls high-pressure winds to spray gangue and impurities to realize accurate, efficient, energy-saving and fully-automatic coal sorting.

PIDS Belt Intelligent Dry Sorting Machine not only realizes fully automatic raw coal sorting with more than 95% recognition accuracy, but also is able to overcome environments unsuitable for traditional wet beneficiation, such as lack of water, severe cold, and easy sludging of ores, etc., and improves the lifespan and value of the mines with a greener and more environmentally friendly sorting process.

Taihe Zhuo Hai VCS/VDS Vertical Intelligent Dry Sorting Machine utilizes dual-energy X-ray scanning imaging system to collect the image of free-falling/chute-falling materials, with higher signal-to-noise ratio, wider adaptability to the particle size, and the lower limit of the sorting particle size is as low as 6mm. the materials are free-falling to the chute after discharging from the vibrating screen, with no physical contact throughout the whole process, so there is no risk of mechanical failure; the spraying system is arranged horizontally, so it is not easy to be blocked. The material can be accelerated to 3m/s when it falls to the lookout point, and the speed is about 5m/s when it falls to the execution point, which is 30% higher than the processing capacity of belt-type intelligent dry separator under the same conditions.

Recently, Taihe Zhuo Hai successfully won the bidding of Zhangbei Coal Beneficiation Plant Intelligent Dry Selection Project of Huainan Mining Group Coal Beneficiation Branch.

The PIDS Belt Intelligent Dry Separation Equipment of Zhangbei Coal Processing Plant, which won the bid, is the fifth project between Taihe Zhuo Hai and Huainan Mining Group after Ordos Tangjiahui Project, Huainan Zhangji Project, Guqiao Project and Xieqiao Project. Among them, Huainan Zhangji Intelligent Dry Separation Project was put into operation at the beginning of 2021, up to now, the operation is very stable, and the proportion of coal in the gangue has decreased from 8% to less than 3%, which increases the income of the enterprise by more than 5 million RMB every year, and other projects are also in stable operation.

The winning bid of intelligent dry sorting equipment of Zhangbei Coal Processing Plant will further promote the comprehensive and deep friendly cooperation between Taihe Zhuohai and Huainan Mining Group, and also marks the further development of Taihe Zhuohai's coal intelligent dry sorting market in Anhui Province, and continues to remain at the forefront of the field of intelligent dry sorting of coal and provide intelligent equipment and services for the automation and intelligent upgrading of the mines and other industries, and improve the life span of the mines with a greener and more environmentally friendly sorting process and value.

PIDS Belt Intelligent Dry Sorting Machine utilizes dual-energy X-ray/visible full-spectrum multispectral scanning imaging system to collect images of materials on the conveyor belt, analyzes the images and determines the type of materials through deep learning image recognition technology, and accurately controls high-pressure winds to spray gangue and impurities to realize accurate, efficient, energy-saving and fully-automatic coal sorting.

PIDS Belt Intelligent Dry Sorting Machine not only realizes fully automatic raw coal sorting with more than 95% recognition accuracy, but also is able to overcome environments unsuitable for traditional wet beneficiation, such as lack of water, severe cold, and easy sludging of ores, etc., and improves the lifespan and value of the mines with a greener and more environmentally friendly sorting process.

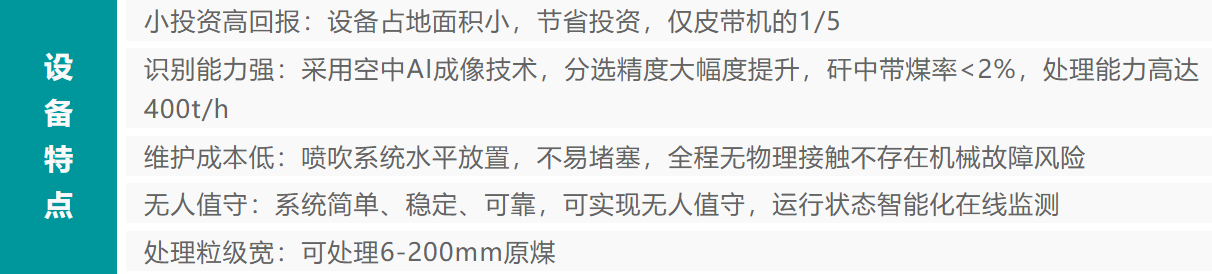

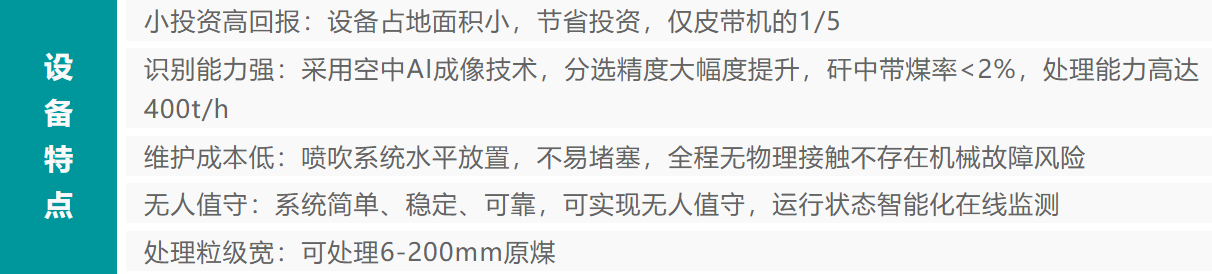

Taihe Zhuo Hai VCS/VDS Vertical Intelligent Dry Sorting Machine utilizes dual-energy X-ray scanning imaging system to collect the image of free-falling/chute-falling materials, with higher signal-to-noise ratio, wider adaptability to the particle size, and the lower limit of the sorting particle size is as low as 6mm. the materials are free-falling to the chute after discharging from the vibrating screen, with no physical contact throughout the whole process, so there is no risk of mechanical failure; the spraying system is arranged horizontally, so it is not easy to be blocked. The material can be accelerated to 3m/s when it falls to the lookout point, and the speed is about 5m/s when it falls to the execution point, which is 30% higher than the processing capacity of belt-type intelligent dry separator under the same conditions.