Food Security | Zengran Packaging Deeply Plows Intelligent Production, Helps Quality Grain Project

Release Date:2020-10-16 Source: Number of views:1005

As the saying goes, "Food is the God of the people, food safety is the first", food safety has always been the focus of national attention, food safety supervision workload is huge, food safety accidents occur frequently and the causes are variable, so it is difficult to rely on the traditional manual mode of supervision to achieve immediate warning of food safety problems and effective monitoring.

The application of artificial intelligence regulatory model can adapt to the complex and changing forms, through intelligent sorting, intelligent packaging, intelligent loading systems and other advanced technologies can improve the early warning and monitoring of food safety events, the implementation of the main responsibility of corporate food safety, to protect food safety.

As a result of the epidemic, the issue of food security has been emphasized by all countries in the world, and food security and food trade are closely related, with the two being causal and mutually constraining. Different food trade policies have a direct impact on the level of food security, while changes in the level of food security promote the innovation of new trade policies. Therefore, in the current economic and social context, it is particularly important to ensure food security in China.

Intelligent sorting to safeguard grain quality at source

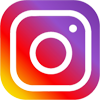

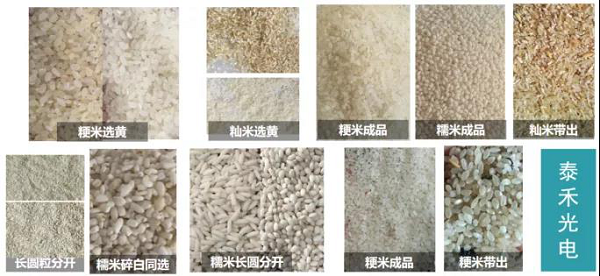

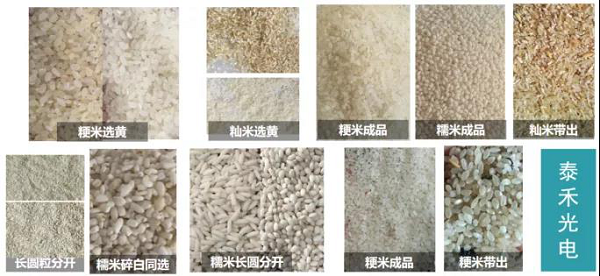

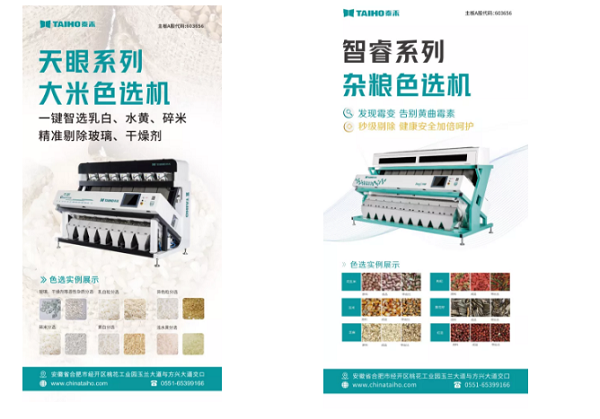

Intelligent sorting, as a necessary part of the grain industry's deep processing, plays a role in checking the quality of grain from the source. Taking rice as an example, Taiho photoelectric eye of heaven series color sorter uses multi-spectrum confocal technology, which can accurately eliminate transparent glass, desiccant, foreign-color plastics and other harmful malignant impurities in rice; at the same time, its powerful AI algorithm function can one-key intelligent selection of milky white grain, light water yellow, broken rice, paddy, and grass seed; through the shape selection+color sorting technology, it can realize simultaneous sorting of rice's oblong, broken white, and yellow-white.

(Intelligent Sorting Comparison)

With people's continuous pursuit of better life and rapid increase in awareness of food safety, higher requirements have been put forward to strengthen the cleaning of malignant impurities and pesticide residues in grain. Taiho Optoelectronics Tianye and Zhirui series of intelligent sorting equipments exhibited in this exhibition can efficiently complete the shape selection, quality selection and color selection of grains to ensure the safety of grains and guarantee the quality of grains.

Intelligent packaging, the guardian of grain quality

After intelligent sorting of grain, the grain is packaged through intelligent equipment. Good packaging can play the role of moisture-proof and mildew-proof, pest-proof and rodent-proof, slowing down aging, preserving quality and freshness, etc. At the same time, it is convenient to use, easy to load and unload and transport, and beautify the image of the product in order to promote the sales of grain. "Zengran brand packaging machinery and equipment, for the characteristics of the grain industry, granule packaging unit can pack 25~50kg/bag of grain, 5000B packaging unit can pack (50~340) x (80~260) mm bag making range (length x width) of pouch packaging.

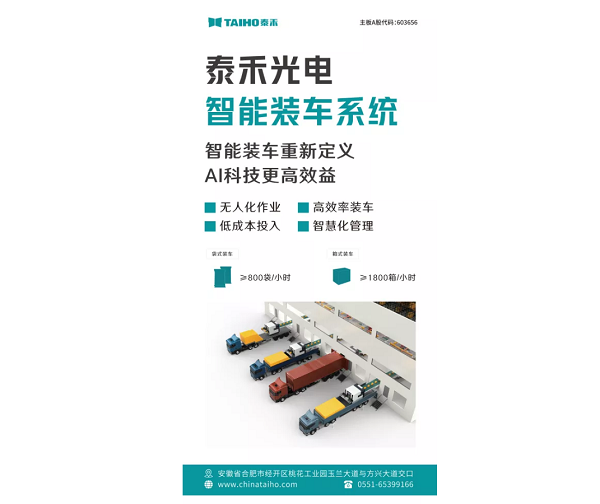

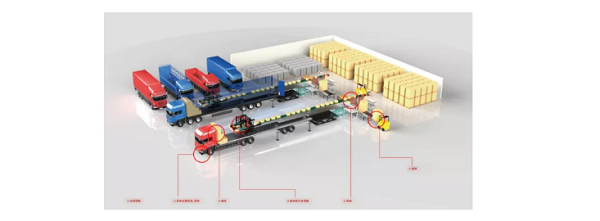

Intelligent loading, grain and oil industry loading solution experts

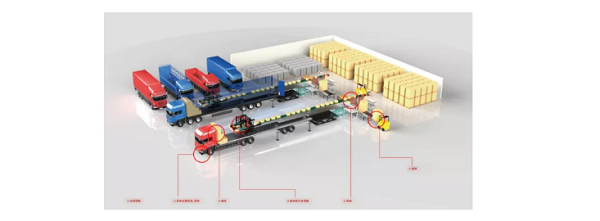

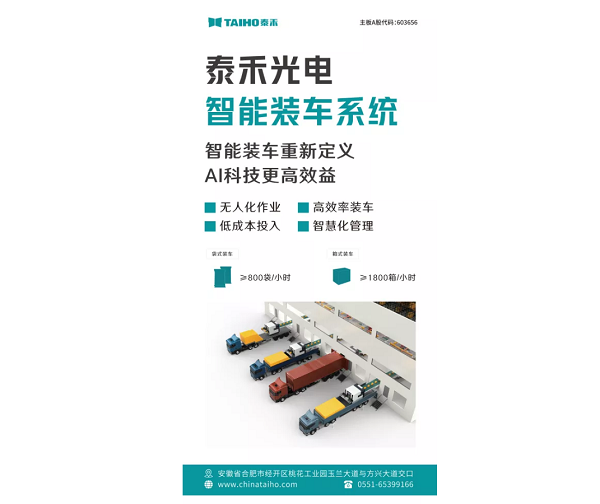

Today, with the rapid development of science and technology, the traditional loading method has high cost, low efficiency and serious safety hazards, so it is urgent to upgrade and transform. Taiho photoelectric intelligent loading system realizes unmanned, informatized and intelligent operation of the whole loading process, helping to build the last link of "smart factory". It is widely used in grain and oil, chemical industry, home appliances, wine and beverage industry, etc. It increases efficiency by 30% and reduces cost by 40% compared with traditional loading, which further accelerates the technological transformation of grain processing enterprises and promotes the process of high-quality grain project.

In order to better serve grain enterprises, Zengran Packaging, together with its parent company Taiho Optoelectronics, participated in the 2020 Third Grain Trade Conference on October 19-21 at the Fuzhou Strait International Convention and Exhibition Center, and brought intelligent sorting--intelligent packaging--intelligent loading system and other production and processing equipments to grain enterprises for live demonstration. Intelligent loading system and other production and processing equipment, on-site hands-on demonstration, customer manager explains the whole process, help enterprises to solve the problem of food security. On the exhibition site, grain enterprises are welcome to bring material to try the machine, October 19, we sincerely invite you to participate in the Fuzhou Strait International Convention and Exhibition Center with you.

As the saying goes, "Food is the God of the people, food safety is the first", food safety has always been the focus of national attention, food safety supervision workload is huge, food safety accidents occur frequently and the causes are variable, so it is difficult to rely on the traditional manual mode of supervision to achieve immediate warning of food safety problems and effective monitoring.

The application of artificial intelligence regulatory model can adapt to the complex and changing forms, through intelligent sorting, intelligent packaging, intelligent loading systems and other advanced technologies can improve the early warning and monitoring of food safety events, the implementation of the main responsibility of corporate food safety, to protect food safety.

As a result of the epidemic, the issue of food security has been emphasized by all countries in the world, and food security and food trade are closely related, with the two being causal and mutually constraining. Different food trade policies have a direct impact on the level of food security, while changes in the level of food security promote the innovation of new trade policies. Therefore, in the current economic and social context, it is particularly important to ensure food security in China.

Intelligent sorting to safeguard grain quality at source

Intelligent sorting, as a necessary part of the grain industry's deep processing, plays a role in checking the quality of grain from the source. Taking rice as an example, Taiho photoelectric eye of heaven series color sorter uses multi-spectrum confocal technology, which can accurately eliminate transparent glass, desiccant, foreign-color plastics and other harmful malignant impurities in rice; at the same time, its powerful AI algorithm function can one-key intelligent selection of milky white grain, light water yellow, broken rice, paddy, and grass seed; through the shape selection+color sorting technology, it can realize simultaneous sorting of rice's oblong, broken white, and yellow-white.

(Intelligent Sorting Comparison)

With people's continuous pursuit of better life and rapid increase in awareness of food safety, higher requirements have been put forward to strengthen the cleaning of malignant impurities and pesticide residues in grain. Taiho Optoelectronics Tianye and Zhirui series of intelligent sorting equipments exhibited in this exhibition can efficiently complete the shape selection, quality selection and color selection of grains to ensure the safety of grains and guarantee the quality of grains.

Intelligent packaging, the guardian of grain quality

After intelligent sorting of grain, the grain is packaged through intelligent equipment. Good packaging can play the role of moisture-proof and mildew-proof, pest-proof and rodent-proof, slowing down aging, preserving quality and freshness, etc. At the same time, it is convenient to use, easy to load and unload and transport, and beautify the image of the product in order to promote the sales of grain. "Zengran brand packaging machinery and equipment, for the characteristics of the grain industry, granule packaging unit can pack 25~50kg/bag of grain, 5000B packaging unit can pack (50~340) x (80~260) mm bag making range (length x width) of pouch packaging.

Intelligent loading, grain and oil industry loading solution experts

Today, with the rapid development of science and technology, the traditional loading method has high cost, low efficiency and serious safety hazards, so it is urgent to upgrade and transform. Taiho photoelectric intelligent loading system realizes unmanned, informatized and intelligent operation of the whole loading process, helping to build the last link of "smart factory". It is widely used in grain and oil, chemical industry, home appliances, wine and beverage industry, etc. It increases efficiency by 30% and reduces cost by 40% compared with traditional loading, which further accelerates the technological transformation of grain processing enterprises and promotes the process of high-quality grain project.

In order to better serve grain enterprises, Zengran Packaging, together with its parent company Taiho Optoelectronics, participated in the 2020 Third Grain Trade Conference on October 19-21 at the Fuzhou Strait International Convention and Exhibition Center, and brought intelligent sorting--intelligent packaging--intelligent loading system and other production and processing equipments to grain enterprises for live demonstration. Intelligent loading system and other production and processing equipment, on-site hands-on demonstration, customer manager explains the whole process, help enterprises to solve the problem of food security. On the exhibition site, grain enterprises are welcome to bring material to try the machine, October 19, we sincerely invite you to participate in the Fuzhou Strait International Convention and Exhibition Center with you.